Aluminum Coil For Tanker

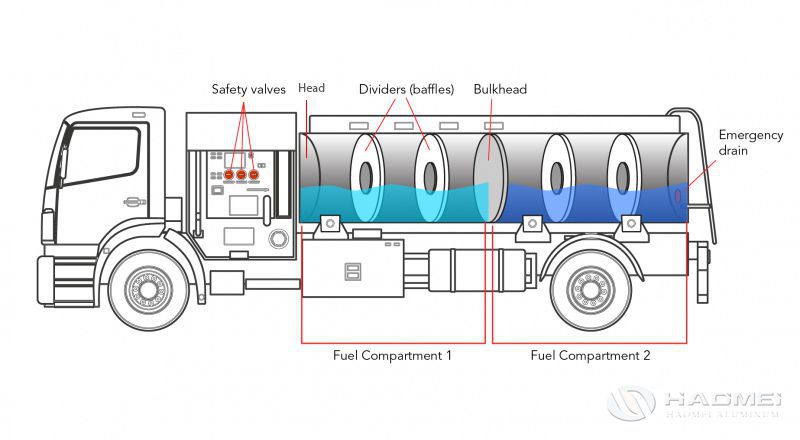

The 5000 series aluminum coil for tanker are high strength aluminum-magnesium alloy in the oil and fuel tank truck processing industry. Because the 5083, 5182, 5454 aluminum alloy have light weight, good corrosion resistance, weldable performance and excellent corrosion resistance. It is these excellent properties, they are widely used in vessel such as oil tanker, tank trucks, fuel tanker etc.

Tanker aluminum coil in the transport vehicle main feature is that good durability and corrosion resistance, because the tanker is made of aluminum plate is light, the whole vehicle itself reduce, at the same time, can achieve the effect of energy conservation and emissions reduction.

With the development and upgrading of the aluminum coil for tankers, its excellent corrosion resistance, weldability and other characteristics are reflected in the tanker body manufacturing. Currently the aluminum is used instead of steel plate gradually.

Specification of Aluminum Coil For Tanker:

Product Type | Alloy | Temper | Thickness (mm) | Width(mm) | |

Coil | Wide Plate | 5083, 5182, 5454 | O, H12, H14, H22, H111, H112, H32, etc. | 4-8 | 2200-2600 |

Standard Plate | 4-8 | 1500-2200 | |||

Chemical Composition of Aluminium Coil For Tanker:

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Standard |

5083 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | EN573 |

5182 | 0.20 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.10 | 0.25 | 0.10 | |

5454 | 0.25 | 0.40 | 0.10 | 0.50-1.0 | 2.4-3.0 | 0.05-0.20 | 0.25 | 0.20 |

Mechanical Properties of Aluminum Coil For Oil Tanker:

Alloy | Temper | Yield Strength | Tensile Strength | Elongation | 180°Min. Bend Radius | Standard |

5083 | O/H111 | ≥145 | 290-370 | ≥17 | 1.5t | EN14286 |

5083 | H32 | ≥215 | 305-385 | ≥12 | -- | ASTM B209 |

5182 | O/H111 | ≥125 | 280-350 | ≥26 | t | EN14286 |

5454 | O/H111 | ≥85 | 215-285 | ≥19 | t | EN14286 |

5454 | H32 | ≥180 | 250-305 | ≥12 | -- | ASTM B209 |

Advantages of Aluminum Coil For Tankers:

1.The weight aluminum coil for tanker is light.

The tanker aluminum coil is only 2.71g/cm3, and the same volume of aluminum alloy is almost only 1/3 of the weight of steel. The application of aluminum alloy on the tanker greatly reduces its own weight.

2. The aluminum coil for oil tanker has strong corrosion resistance.

Aluminum alloy has incomparable corrosion resistance than steel. The tank is made of aluminum alloy and can transport various liquids or liquefied gases without any protective layer inside. Because the aluminum alloy tank has good corrosion resistance, it can ensure cleaner oil.

3. The recovery value of the aluminum coil for tanker is high.

The aluminum coil has strong corrosion resistance. After the can is forced to scrap, the aluminum alloy can has no major damage and can be recycled and reused.

4. The tanker aluminum coil has good electrical conductivity and energy absorption performance, and is safer.

When the tanker collides, because the aluminum alloy has good electrical conductivity, little static electricity is collected on the tank body, so no sparks will be generated, thereby reducing the occurrence of accidents such as explosions.

Application of Aluminum Coil For Tank Truck:

1) Oil tanker

2) Fuel tanker

3) LNG storage tank

4) Semi Trailer