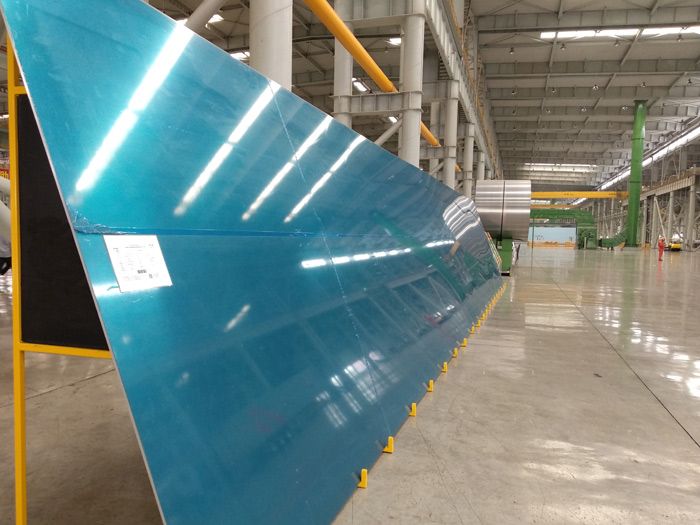

Aluminum For Tank Truck

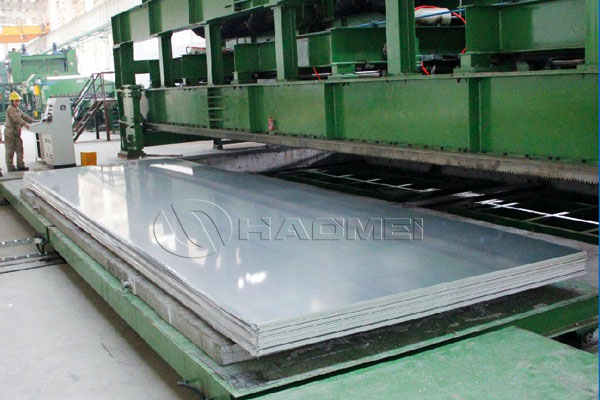

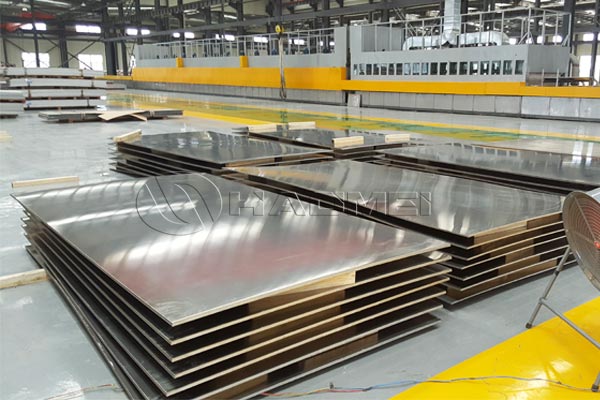

Alloys of Aluminium For Tank Truck

5083 aluminum plate for tanker is a widely used in the manufacturing of fuel trucker. Its main element is magnesium, which has good welding performance, corrosion resistance and processing performance and medium strength.

5182 aluminum plate is used for the the latest high-magnesium alloy tanker which was born for the European road dangerous goods transportation agreement in recent years. Its tensile strength and elongation are relatively high. The excellent quality of 5182 alloy plate improves the safety of aluminum alloy tankers.

5454 aluminium plate is suitable for aluminum-magnesium alloy tankers used under high temperature conditions, with strong corrosion resistance.

Specification of Aluminum For Tank Truck:

Alloy | Temper | Product Type | Thickness (mm) | Width(mm) | Length(mm) | |

5083, 5182, 5454, 5754, 5059 | O, H12, H32, H111, H112 | Plate | Wide Plate | 4-8 | 2200-2600 | 2000-12000 |

Standard Plate | 4-8 | 1500-2200 | 2000-12000 | |||

Coil | Wide Plate | 4-8 | 2200-2600 | - | ||

Standard Plate | 4-8 | 1500-2200 | - | |||

Remark:Typical width for tanker body and resistance plate: 1500/1600/1800/2000/2200/2400mm

Typical length: 5500/5750/6000/7500/7850/8600/11800mm

Quality Control Points

Part | Control Points | ||

Barrel, head | Surface quality Mechanical Property Thickness tolerance | -- | Flatness |

Wall partition,Resistance plate | Mechanical Property Thickness tolerance | Surface Quality | Flatness |

Chemical Composition of Aluminum Plate For Tank Truck:

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Standard |

5083 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | EN573 |

5182 | 0.20 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.10 | 0.25 | 0.10 | |

5454 | 0.25 | 0.40 | 0.10 | 0.50-1.0 | 2.4-3.0 | 0.05-0.20 | 0.25 | 0.20 |

Mechanical Properties of Aluminium Plate For Tank Truck:

Alloy | Temper | Yield Strength | Tensile Strength | Elongation | 180°Min. Bend Radius | Standard |

5083 | O/H111 | ≥145 | 290-370 | ≥17 | 1.5t | EN14286 |

5083 | H32 | ≥215 | 305-385 | ≥12 | -- | ASTM B209 |

5182 | O/H111 | ≥125 | 280-350 | ≥26 | t | EN14286 |

5454 | O/H111 | ≥85 | 215-285 | ≥19 | t | EN14286 |

5454 | H32 | ≥180 | 250-305 | ≥12 | -- | ASTM B209 |

Advantages of Aluminum Sheet For Tank Truck:

1. The aluminum alloy tank truck has a lighter weight due to the use of aluminum alloy material. By reducing its own weight, the payload of the entire vehicle can be increased. The weight of a single transported cargo is 18% -35 higher than that of a carbon steel tanker.

2. The chemical properties of aluminum alloy are stable, and the corrosion resistance of aluminum alloy is more than 70% higher than that of ordinary carbon steel. The enhanced corrosion resistance greatly reduces the related maintenance cost of the tank.

3. From the appearance point of view, the appearance of the aluminum alloy tanker is more beautiful, and it is easy to clean without painting.

4. Service life. The excellent characteristics of aluminum alloy make the service life of aluminum alloy tank trucks longer. Old aluminum alloy tanks with better maintenance can also be used on new chassis, even if the tanks are scrapped, there is a higher recovery rate value.

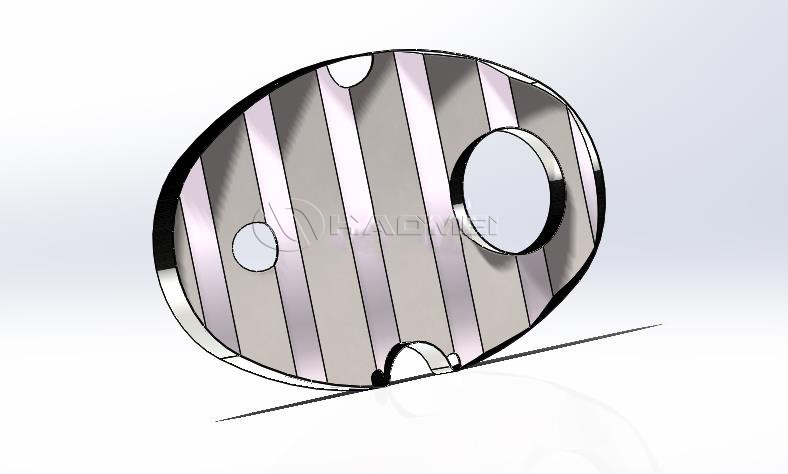

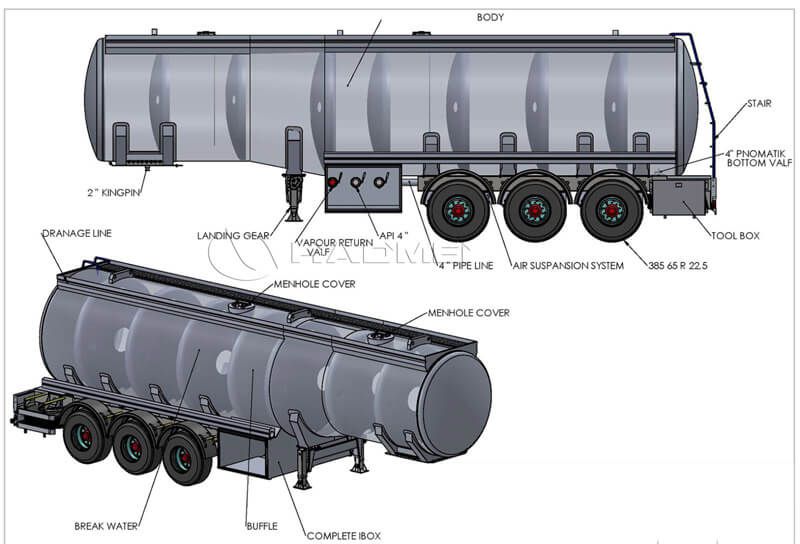

Application of Aluminum Plate For Tanker Truck:

1, The aluminum plate for tank truck is welded with aluminum alloy plate. The plate thickness is 5~6mm.

2, The other parts like wash board, bulkhead and tank head is also of 5000 series aluminum plate. The wall thickness of the tanker head is equal to or greater than that of the tank truck body. The thickness of the bulkhead and wash board is 1mm thinner than the tank body.

3, The thickness of the left and right support plates at the bottom of the tank is 6-8mm, and the material is 5000 aluminum plate. There are guardrails and walking platforms on the top of the tank. The walking platforms are made of aluminum tread plate.